How to Install AC Systems in Mobile Homes in Tampa, FL

Installing an AC system in a mobile home requires a practical understanding of how these homes behave under thermal stress.

Mobile homes across Tampa, Florida, face unique cooling challenges that traditional houses rarely encounter. Construction methods, space constraints, and climate exposure all shape how air conditioning systems perform in these structures. Many mobile homes were designed with minimal insulation, lightweight materials, and compact mechanical spaces, which complicates modern cooling upgrades. As Tampa’s heat and humidity continue to intensify, installing the right air conditioning system becomes less about convenience and more about protecting comfort, health, and the home's longevity.

Installing an AC system in a mobile home requires a practical understanding of how these homes behave under thermal stress. Air moves differently through narrower layouts, walls respond faster to outdoor temperature swings, and moisture intrusion can escalate quickly when systems are poorly selected or installed. A successful installation balances equipment choice, airflow design, electrical capacity, and moisture control in a way that respects the realities of mobile home construction rather than imposing solutions designed for site-built houses.

How Mobile Home Construction Affects AC Installation

Mobile homes differ structurally from site-built houses in ways that directly impact air conditioning installation. Framing materials are lighter, wall cavities are shallower, and roof systems often provide limited attic space. These design characteristics restrict duct routing options and reduce tolerance for oversized or poorly balanced systems. Attempting to install conventional residential AC equipment without accounting for these differences often results in airflow issues and uneven cooling.

Floor plans also influence system behavior. Mobile homes typically feature long, narrow layouts that make even air distribution difficult. Rooms at opposite ends of the home experience different cooling demands, especially during peak Tampa summer afternoons. Without thoughtful system design, one end of the home may feel overly cold while the other struggles with heat and humidity. Understanding how air travels through these spaces helps avoid comfort imbalances that frustrate homeowners after installation.

Structural flexibility presents another consideration. Mobile homes shift more than site-built structures due to their foundations and materials. Refrigerant lines, duct connections, and condensate drains must accommodate slight movement without developing leaks or restrictions. Installation techniques that work well in rigid structures may fail over time in mobile homes if flexibility is not built into the system design from the start.

Evaluating Existing HVAC Setup And Limitations

Before selecting a new air conditioning system, evaluating the existing setup reveals critical limitations. Many older mobile homes rely on packaged units or aging central systems that struggle with Tampa’s humidity. Ductwork may run through unconditioned spaces beneath the home, exposing it to moisture, pests, and temperature extremes that degrade performance over time. Identifying these weak points shapes better replacement decisions.

Electrical capacity often limits available options. Mobile homes often use smaller electrical panels with limited circuit capacity. Installing higher-capacity systems without upgrading the electrical infrastructure leads to breaker trips and unsafe operating conditions. Evaluating panel size, wiring condition, and grounding helps determine whether electrical improvements must accompany AC installation.

Ventilation pathways also deserve attention. Some mobile homes lack proper return air pathways, forcing systems to pull air unevenly through doors and gaps. This imbalance increases humidity problems and reduces efficiency. Recognizing ventilation limitations allows installers to address airflow issues rather than layering new equipment on top of existing problems.

Choosing Between Central AC And Ductless Systems

Central air conditioning remains a common choice for mobile homes with existing ductwork. When ducts are in good condition and properly sized, replacing the outdoor condenser and indoor air handler can restore comfort efficiently. Central systems offer familiar operation and conceal most components, which many homeowners prefer aesthetically.

However, ductless mini split systems provide an alternative when ductwork is damaged, poorly designed, or nonexistent. Mini splits deliver conditioned air directly to living spaces without relying on underfloor ducts exposed to Tampa’s moisture. This approach improves efficiency and reduces the risk of duct-related humidity issues that plague many older mobile homes.

Each option carries tradeoffs. Central systems depend heavily on duct integrity and insulation quality. Ductless systems introduce visible indoor units but allow zoning and independent temperature control. Selecting between these approaches requires an honest assessment of existing conditions rather than defaulting to what seems simplest or cheapest upfront.

Sizing AC Systems For Mobile Homes In Tampa

Proper sizing remains one of the most critical aspects of AC installation in mobile homes. Oversized systems cool air too quickly, shutting down before removing sufficient moisture. In Tampa’s climate, this results in clammy indoor conditions and accelerated material deterioration. Undersized systems run continuously, driving up energy costs and still failing to maintain comfort during extreme heat.

Mobile homes respond quickly to outdoor temperature changes due to their lighter construction materials. Heat gain occurs more quickly, but the internal volume remains smaller than in site-built homes. Accurate load calculations account for insulation levels, window placement, shading, and occupancy patterns. Guessing based on square footage alone leads to poor outcomes.

Humidity load deserves equal consideration. Tampa’s moisture levels demand systems capable of sustained operation at lower output levels. Equipment that modulates capacity rather than cycling aggressively maintains more consistent indoor conditions. Proper sizing protects both comfort and system longevity while reducing strain on electrical components.

Managing Humidity And Moisture Risks

Humidity control represents one of the biggest challenges in mobile homes. Floors, walls, and ceilings contain materials that absorb moisture readily. Without proper dehumidification, moisture can accumulate beneath flooring, in wall cavities, and around windows. Over time, these conditions contribute to odor issues, material degradation, and indoor air quality concerns.

Air conditioning systems that short cycle worsen moisture problems. Cooling air quickly without sustained runtime leaves humidity behind. Selecting equipment designed for longer, steadier operation improves moisture removal. Ductless systems often perform well in this regard because they use variable-speed compressors that adjust output gradually.

Installation details matter just as much as equipment selection. Condensate drainage must function reliably beneath the home where access remains limited. Improper slope or routing allows water to pool, increasing the risk of mold and pests. Thoughtful moisture management protects the home beyond immediate comfort improvements.

Electrical And Power Supply Considerations In Mobile Homes

Electrical infrastructure often limits AC options in mobile homes more than homeowners expect. Many mobile homes in Tampa were built with smaller electrical panels designed for minimal loads. Adding a modern air conditioning system without evaluating available amperage risks frequent breaker trips, voltage drops, and premature equipment failure. These issues rarely appear immediately but tend to surface during peak summer demand, when the system works hardest and electrical stress is highest.

Upgrading the electrical service is sometimes part of a successful AC installation. Dedicated circuits, improved grounding, and panel upgrades support reliable operation and reduce fire risk. Mobile homes also respond poorly to inconsistent voltage, which can damage compressors and control boards over time. Addressing electrical limitations during installation protects the investment and prevents repeated service calls tied to infrastructure rather than equipment defects.

Airflow Design And Distribution Challenges

Airflow in mobile homes differs due to narrow layouts and compartmentalized rooms. Long hallways, closed-off bedrooms, and limited return air pathways create pressure imbalances that reduce system efficiency. Without proper airflow design, cooled air fails to reach distant rooms evenly, leaving occupants adjusting thermostats constantly without resolving comfort issues.

Return air placement plays a critical role. Many mobile homes rely on a single central return that struggles to pull air from the far ends of the structure. This imbalance forces systems to work harder while delivering inconsistent results. Improving airflow through additional returns, better duct balancing, or strategically placing ductless units enhances comfort and reduces strain on the system.

Air leakage compounds these challenges. Gaps around doors, windows, and floor penetrations allow conditioned air to escape quickly. Addressing airflow and leakage together creates a more stable indoor environment, allowing the AC system to operate efficiently rather than constantly fighting losses.

Outdoor Unit Placement And Site Conditions

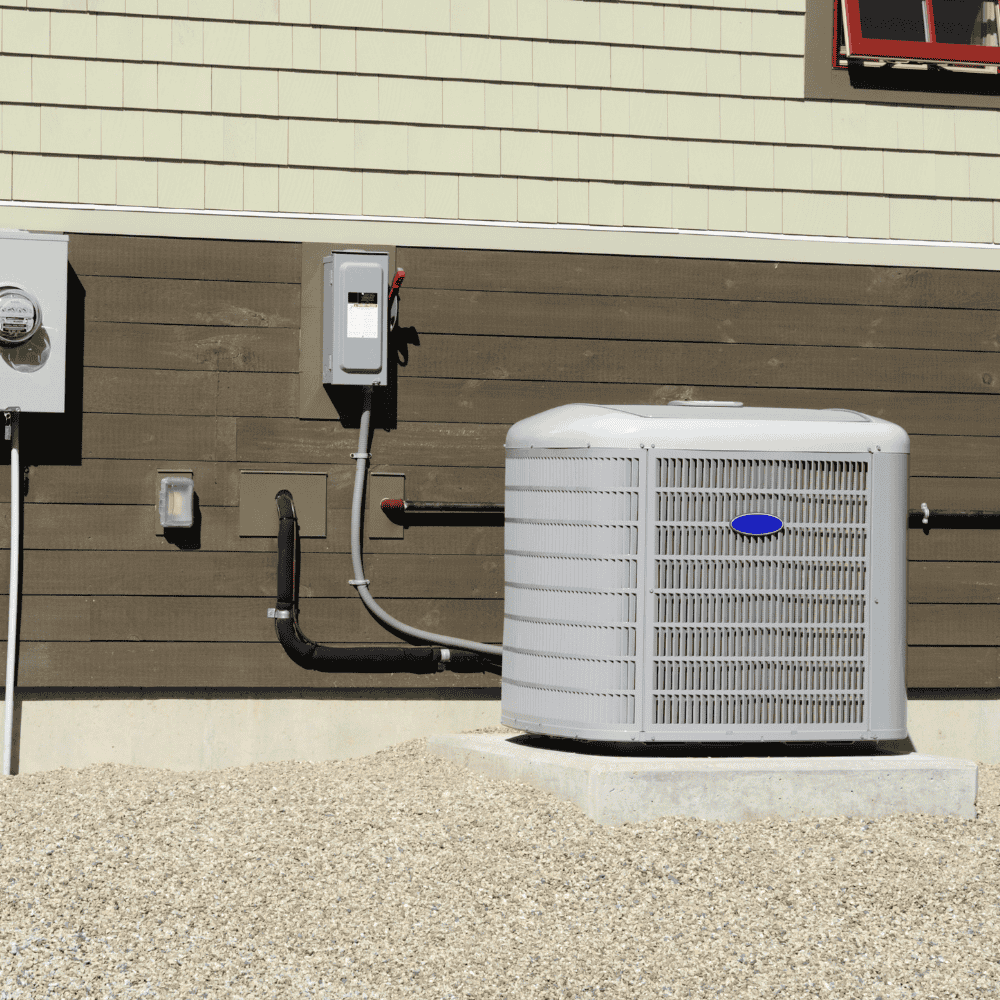

Outdoor condenser placement matters significantly in mobile home installations. Limited yard space, proximity to skirting, and exposure to direct sunlight all affect system performance. Condensers placed too close to the home restrict airflow and increase operating temperatures, reducing efficiency during Tampa’s hottest months.

Elevation also plays a role. Condensers installed on unstable pads shift over time as soil settles or storms pass through. Movement stresses refrigerant lines and electrical connections, increasing the risk of leaks and failures. Proper mounting on reinforced pads or brackets improves stability and protects long-term operation.

Environmental exposure remains another factor. Coastal air, heavy rain, and debris accumulation affect outdoor components. Thoughtful placement reduces corrosion and simplifies maintenance access, which matters greatly during peak cooling season when service demand remains high across Tampa.

Maintenance Planning For Mobile Home AC Systems

Maintenance expectations differ slightly in mobile homes due to system placement and environmental exposure. Ductwork beneath the home requires periodic inspection for moisture intrusion, insulation damage, and pest activity. Neglecting these areas reduces efficiency and introduces air quality concerns that affect occupants directly.

Ductless systems shift maintenance responsibility indoors. Filters at each indoor unit require regular cleaning to maintain airflow and humidity control. Homeowners who understand this responsibility experience better performance and fewer breakdowns. Clear maintenance routines established during installation help avoid neglect that shortens system lifespan.

Seasonal inspections benefit mobile homes more than many homeowners realize. Catching drainage issues, electrical wear, or airflow imbalances early prevents damage that escalates quickly due to the home’s lighter construction. Maintenance becomes part of protecting the structure, not just the equipment.

Energy Efficiency And Operating Costs In Tampa

Energy efficiency remains a major concern for mobile home owners facing long cooling seasons. Lightweight construction allows heat to penetrate quickly, increasing system runtime during peak afternoons. Selecting efficient equipment alone does not solve this issue without addressing insulation, sealing, and shading strategies.

Ductless systems often reduce operating costs by eliminating duct losses and allowing targeted cooling. Central systems benefit from duct sealing and insulation upgrades beneath the home. Both approaches perform best when paired with weatherization improvements that reduce heat gain and air leakage.

Operating cost stability matters as much as efficiency ratings. Systems that run steadily at lower output consume less energy than those cycling aggressively. In Tampa’s climate, consistency supports comfort, humidity control, and predictable utility bills across the summer months.

Long-Term Durability And Replacement Planning

Mobile homes place different stresses on air conditioning systems than site-built houses. Movement, moisture exposure, and electrical variability all affect equipment longevity. Selecting systems designed for durability in these conditions reduces replacement frequency and long-term ownership costs.

Installation quality influences durability more than brand selection alone. Flexible line sets, protected wiring, and proper drainage accommodate structural movement over time. Skipping these considerations leads to failures that appear random but stem from installation shortcuts rather than equipment defects.

Replacement planning also matters. Systems chosen with service accessibility and future compatibility in mind simplify eventual upgrades. Homeowners who think beyond immediate installation position their mobile homes for smoother transitions as cooling needs evolve.

FAQs

Central air can be installed if the mobile home has suitable ductwork and electrical capacity. Many installations require duct repairs or electrical upgrades to support reliable operation in Tampa’s climate.

Ductless mini split systems work very well in mobile homes, especially when ductwork is damaged or poorly insulated. They provide efficient cooling and strong humidity control without relying on underfloor ducts.

Mobile homes require careful sizing that accounts for insulation levels, layout, and humidity load. Systems sized solely by square footage often perform poorly in Tampa’s heat and humidity.

Many mobile homes need an electrical evaluation before AC installation. Panel size, wiring condition, and circuit availability determine whether upgrades are necessary to safely support modern equipment.

System lifespan depends on installation quality, maintenance, and environmental exposure. Properly installed and maintained systems can last many years, even in Tampa’s demanding climate.