How Proper Installation Enhances the Longevity of a Heating System

The initial assessment phase establishes a foundation for proper installation procedures that directly impact system durability and efficiency.

Maximizing the lifespan of a heating system begins with meticulous planning and assessment before installation commences. Professional HVAC technicians conduct comprehensive evaluations of the installation space, considering factors such as square footage, insulation quality, and existing ductwork configuration. By analyzing these elements, experienced installers can determine optimal equipment placement and necessary modifications to support peak system performance. The initial assessment phase establishes a foundation for proper installation procedures that directly impact system durability and efficiency.

Equipment Selection and Sizing

Selecting appropriately sized heating equipment represents a critical factor in system longevity. HVAC professionals utilize industry-standard calculations to determine the precise heating capacity required for specific spaces. Oversized systems lead to frequent cycling, increasing wear on components and reducing overall lifespan. Conversely, undersized units strain to maintain desired temperatures, operating continuously and accelerating component degradation. Professional sizing considerations incorporate factors such as local climate patterns, building orientation, and occupancy patterns to recommend equipment that matches exact heating requirements.

Quality of Installation Components

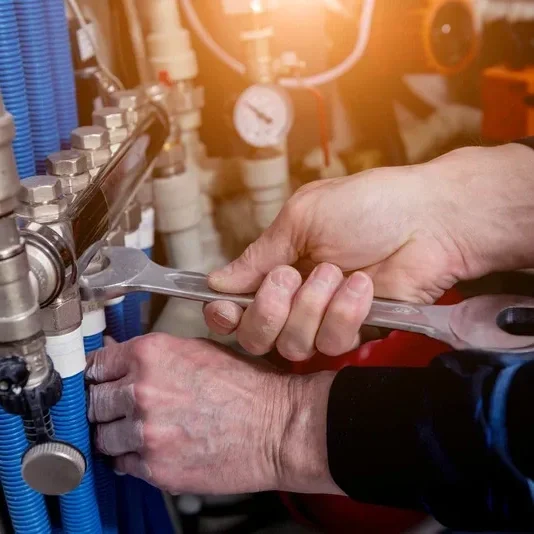

Superior installation practices incorporate high-quality materials and components designed for extended service life. Professional HVAC installations utilize industry-approved mounting hardware, electrical connections, and ducting materials that meet or exceed manufacturer specifications. Proper installation includes careful attention to component compatibility and adherence to recommended clearances for maintenance access. Quality materials contribute significantly to system reliability and reduce the likelihood of premature component failure.

Ductwork Integration and Optimization

Proper duct installation and integration play vital roles in heating system performance and longevity. Professional duct cleaning services before installation remove accumulated debris that could impact new system operation. Careful evaluation of existing ductwork reveals potential issues requiring attention, such as air leaks or inadequate insulation. Skilled installers implement appropriate modifications to optimize airflow distribution and minimize system strain. Well-designed ductwork supports efficient operation while reducing wear on heating system components.

Electrical and Safety Considerations

Professional HVAC installation includes proper electrical connections and safety feature implementation. Licensed technicians verify power supply specifications and install appropriate circuit protection devices. Careful attention to manufacturer wiring diagrams and local electrical codes supports safe, reliable operation. Professional installations incorporate necessary safety switches and monitoring devices to protect equipment from dangerous operating conditions that could shorten system lifespan.

System Calibration and Testing

Thorough calibration and testing procedures following installation verify optimal system performance. HVAC professionals conduct comprehensive operational checks to confirm proper functioning of all components. Advanced diagnostic tools enable precise adjustment of system parameters for maximum efficiency. Professional testing procedures identify potential issues before they develop into significant problems, supporting extended equipment life through early intervention.

Ventilation and Air Quality Features

Proper installation practices account for ventilation requirements and air quality considerations. Professional HVAC installations include appropriate filtration systems and air cleaning devices specified for particular applications. Careful integration of ventilation components supports proper system operation while maintaining healthy indoor air quality. Well-designed ventilation systems reduce strain on heating equipment while extending operational life through improved air handling.

Control System Integration

Modern heating systems benefit from sophisticated control system integration during installation. Professional installers configure thermostats and control devices to optimize system operation. Proper programming of operating parameters prevents excessive cycling and maintains stable temperature control. Advanced control systems enable monitoring of system performance metrics, allowing early detection of potential issues that could impact longevity.

Condensate Management

Professional installation includes proper management of condensate produced during system operation. Skilled technicians install appropriate drainage systems and safety switches to prevent water damage and system malfunction. Proper slope and insulation of condensate lines prevent freezing and blockages that could lead to equipment damage. Well-designed condensate handling systems protect both the heating equipment and surrounding structure.

Documentation and Maintenance Planning

Complete installation documentation supports long-term system maintenance and operation. Professional HVAC installers provide detailed records of equipment specifications, modifications, and initial performance metrics. Establishing regular maintenance schedules based on manufacturer recommendations protects the investment in new heating equipment. Proper documentation enables efficient troubleshooting and repair when necessary, contributing to extended system life.

System Performance Verification

Post-installation performance verification confirms proper system operation under various conditions. HVAC professionals conduct extended testing to evaluate heating distribution, temperature control, and system response. Careful measurement of operating parameters identifies potential adjustments needed for optimal performance. Professional verification procedures establish baseline measurements for future reference during maintenance and service.

Future Maintenance Considerations

Professional installation practices incorporate features that facilitate future maintenance requirements. Skilled installers provide adequate access for component inspection and service. Proper installation of service valves and test ports enables efficient system maintenance. Considering future maintenance needs during installation supports regular upkeep that extends system lifespan.

The relationship between proper installation and heating system longevity cannot be overstated. Professional HVAC installation services provide expertise and attention to detail that directly impact system performance and durability. Through careful planning, quality components, and comprehensive testing, skilled installers create conditions that support extended equipment life. Regular maintenance performed by qualified technicians builds upon the foundation of proper installation, maximizing the return on investment in heating equipment while providing reliable comfort for years to come.